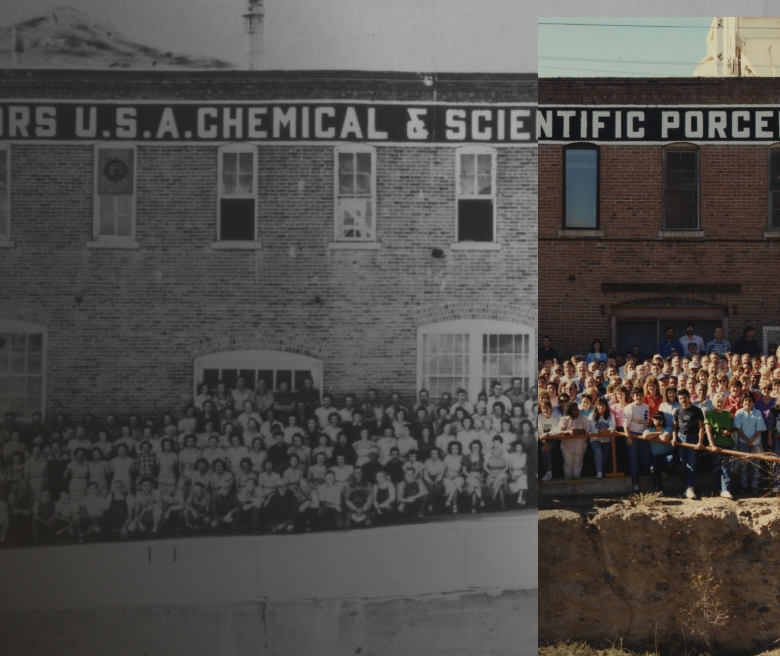

The site has been in a constant state of reinvention throughout its history and that tradition is continuing in delightful new ways.

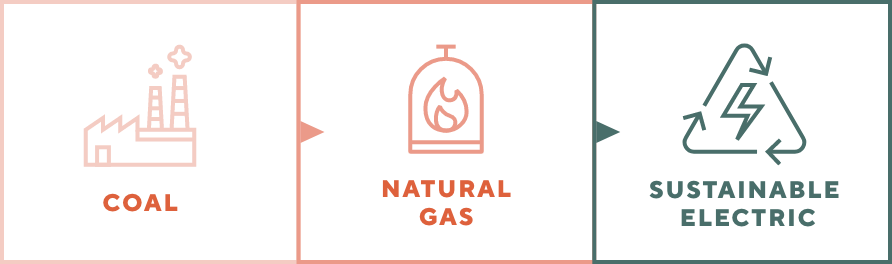

There’s beauty in the pure industrial utility of the structures, form following function. The facility has been in a constant state of evolution, meeting the needs of production and incorporating new technology over the years. The buildings themselves morphing – streamlining and expanding – with market forces. Gone are the old stacks from the coal-fired beehive kilns, for instance, swapped decades later with what at the time was more efficient natural gas and more advanced manufacturing processes. Each generation marks a steady progression towards sustainability. This site has been an economic engine and employment center for the community for over a century and now the time has come to bring a new measure of value to Golden and yet another generation of eco-innovation using electric power from renewable resources.

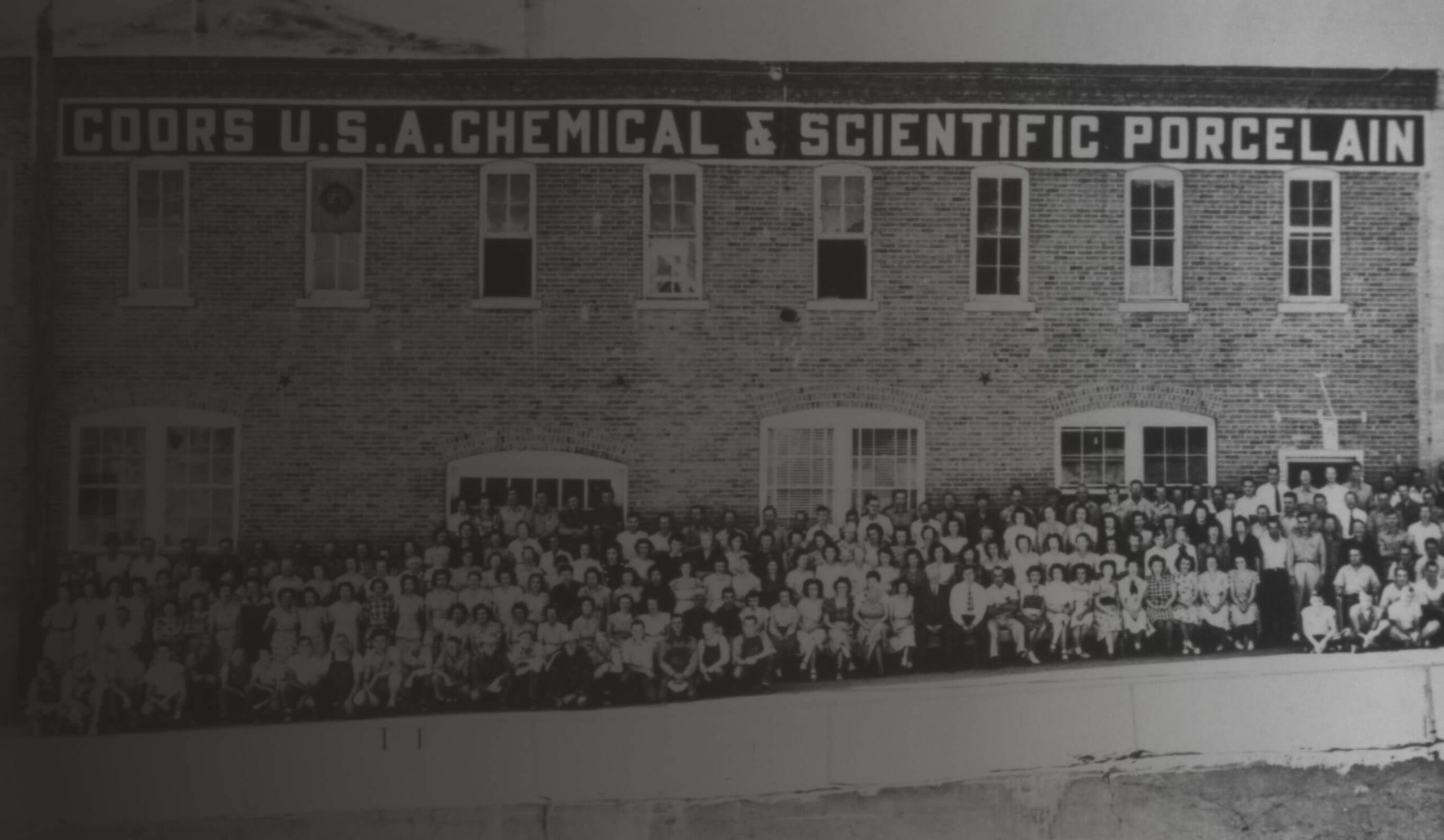

Since its humble 1910 beginnings as Herold China & Pottery, then as Coors Porcelain Company, Coors Ceramics and eventually CoorsTek, this site has seen numerous groundbreaking advancements in engineered ceramics and materials sciences.

The facility has produced fine (now collectible) dinnerware, porcelain labware, ceramic insulators, semiconductors and military-grade ceramic armor – just to name a few – while pioneering kiln technology, manufacturing techniques, and chemical compositions, creating stronger, lighter, more effective ceramic-based products along the way. And in 1959, the inspiration to manufacture beer cans resulted in the recyclable aluminum beverage can we all use today. On a site that’s always been about what’s next, the next chapter couldn’t be more exciting. More at coorstek.com